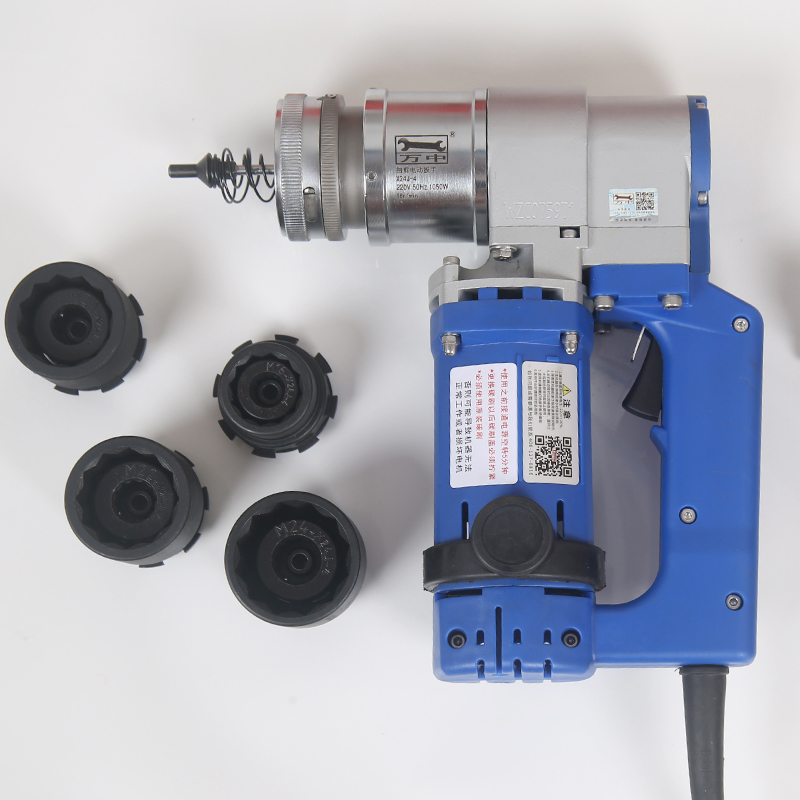

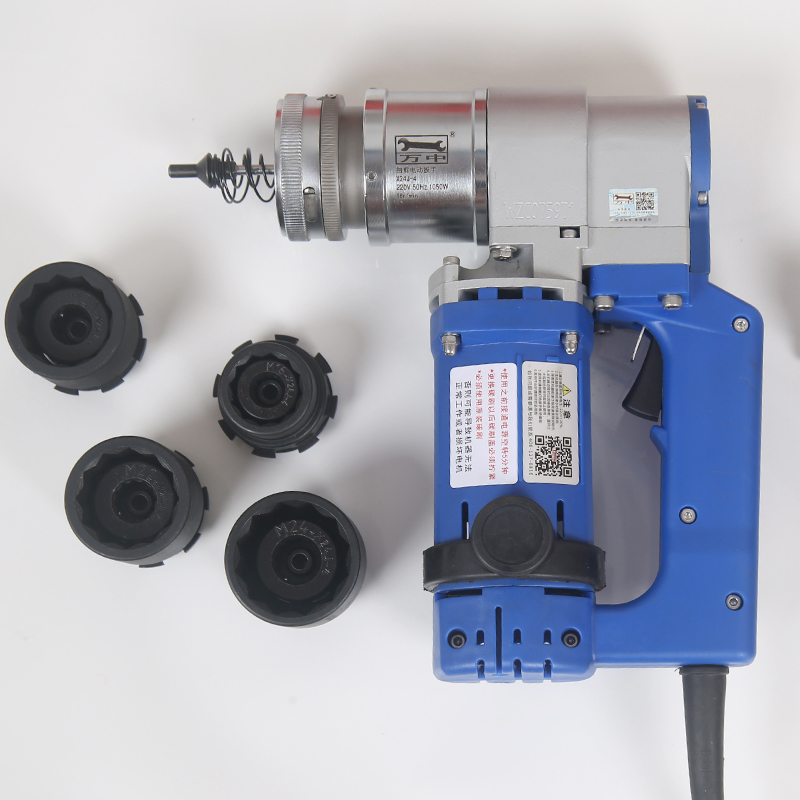

定扭矩电动扳手也称为可调扭矩电动扳手,是电动扳手的一种,扭矩可以设定,扭矩可以调整。主要用于钢结构安装行业,安装钢结构高强度螺栓,高强度螺栓用于连接钢结构触点,一般采用螺栓形式。

A fixed torque electric wrench, also known as an adjustable torque electric wrench, is a type of electric wrench that can set and adjust the torque. Mainly used in the steel structure installation industry, high-strength bolts are installed for connecting steel structure contacts, usually in the form of bolts.

一般来说,高强度螺栓在拧紧前须拧紧,每个阶段都需要严格的扭矩要求。本实用新型涉及一种适用于高密度六角头高强度螺栓端部的固定扭矩电动扳手。

Generally speaking, high-strength bolts must be tightened before tightening, and strict torque requirements are required at each stage. The utility model relates to a fixed torque electric wrench suitable for the ends of high-density hexagonal high-strength bolts.

目前,对固定扭矩电动扳手的研究集中在兼具固定值和过载故障功能的数字显式扭矩电动扳手上,通过LCD显示屏窗口进行人性化设计受到用户的欢迎。此外,还有扭矩值监控终端、峰值设置和警报功能、无线传输功能、与安装的无线传输终端的通信、数据记录和管理。

At present, research on fixed torque electric wrenches is focused on digital explicit torque electric wrenches that have both fixed value and overload fault functions. Humanized design through LCD display windows has been welcomed by users. In addition, there are torque value monitoring terminals, peak setting and alarm functions, wireless transmission functions, communication with installed wireless transmission terminals, data recording and management.

从传统的手指扭矩扳手到具有多种社会功能的数字显式固定扭矩电动扳手,随着信息技术的发展,可以实现质的飞跃。传统的固定扭矩电动扳手有以下几个优点:1.技术持续成熟,性能相对稳定。

From traditional finger torque wrenches to digital explicit fixed torque electric wrenches with various social functions, with the development of information technology, a qualitative leap can be achieved. Traditional fixed torque electric wrenches have the following advantages: 1. The technology continues to mature and the performance is relatively stable.

2.人性化的管理操作系统界面;强大的数据分析和处理的主要功能等。

2. Humanized management operating system interface; The main functions of powerful data analysis and processing.

定扭矩电动扳手缺点:系统组件多任务复杂性文档提出了人工智能扭转扳手系统,包括企业电子标签、扭转扳手、信息资源管理会计软件等。通过开发智能手机芯片来执行必要的功能。使用扳手系统时,须能够同时启动计算机,对螺栓信息进行编号,编写网络信息记录学生管理分析软件,并在相应的螺栓上贴上电子标签。

Disadvantages of fixed torque electric wrenches: The system components are multitasking and complex. The document proposes an artificial intelligence torsion wrench system, including enterprise electronic labels, torsion wrenches, information resource management accounting software, etc. By developing smartphone chips to perform necessary functions. When using the wrench system, it is necessary to be able to simultaneously start the computer, number the bolt information, write a network information security record student management analysis software, and attach electronic labels to the corresponding bolts.

定扭矩电动扳手的功能只有在教育准备培训任务完成后,我们才能充分发挥,效率低下,操作过程复杂。类似的扭力扳手结构比较复杂。准确度和困难是目前市场上的正扭矩电动扳手在准确度和上都是难题。高精度扳手一般是数字定扭矩电动扳手,进口产品一般水平较高。低的是扭转销扳手结构比较简单,准确度低,很难满足人们使用其他要求。这也是为什么定扭矩电动扳手不能在相关知识领域广泛应用的原因之一。

The function of a fixed torque electric wrench can only be fully utilized after the completion of educational preparation and training tasks, resulting in low efficiency and complex operation process. Similar torque wrenches have a more complex structure. The difficulty in accuracy and price is currently a challenge for positive torque electric wrenches in the market. High precision wrenches are generally digital fixed torque electric wrenches, and imported products generally have a higher price level. The lower price is that the torsion pin wrench has a relatively simple structure and low accuracy, making it difficult to meet other requirements for people to use. This is also one of the reasons why fixed torque electric wrenches cannot be widely used in related knowledge fields.

传统的定扭矩电动扳手具有应用扭矩值和监控扭矩值的功能,但为了应用于其他规格的螺栓,须手动设置扭矩值的数量。不同螺栓的预紧力矩值可参考相关手册或公式计算。

Traditional fixed torque electric wrenches have the function of applying torque values and monitoring torque values, but in order to be applied to other specifications of bolts, the number of torque values must be manually set. The pre tightening torque values of different bolts can be calculated by referring to relevant manuals or formulas.